The Forney Museum of Transportation is located at 4303 Brighton Boulevard in Denver, CO.

The collection was begun by J. D. Forney, who gave his name to the museum. Forney Industries was formed in 1932 when James Donovan Forney went into business selling "The Forney Instant Heat Soldering Iron" door to door. In 1936, he invented the first successful 110 volt, 125 and 150 amp welders for use outside an industrial setting.

Over the ensuing years, the company produced products as diverse as the 1959 "Fornaire" two seat airplane designed for the consumer market, a central residential vacuum system, auto generators and battery chargers, but probably the best-known products are the electric welders and welding supplies that the company still produces to this day.

Forney became interested in antique and classic cars after his wife and children gave him a 1921 Kissel yellow Tourister, the same model he used to court his wife Rae. He then started taking in old cars and carriages as trades on some of the welder sales and began to build what is now the current collection.

In 1961, the Forney Museum was incorporated in Fort Collins, CO, and in 1964, it was recognised as a 501(3)(c) non-profit organisation.

In 1986, J. D. Forney passed away, but his legacy lives on in the museum that still bears his name.

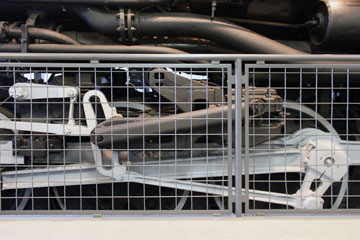

Big Boys were the only steam locomotives built with the 4-8-8-4 type wheel arrangement, and were also amongst the most powerful ever built. Coal burners, the Class 1 Big Boys were fitted with MB automatic stokers and had 150 sq ft grates and

704 sq ft fireboxes. The grates were manufactured by the Waugh Equipment Company and the

firebox was fitted with seven Alco designed circulators.

Operating at a boiler pressure of 300 psi, with 68" drivers and four 23½" x 32" cylinders, Big Boys could deliver 135,375 lbs tractive effort.

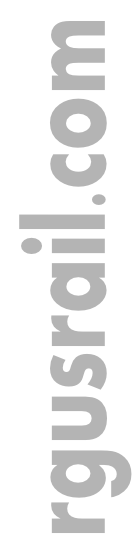

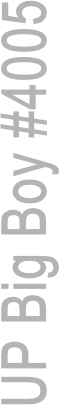

Union Pacific #4005 is one of eight surviving 4-8-8-4 type Big Boys, twenty-five of which were built by Alco to a design by the UP's Department of Research and Mechanical Standards. They were designed to work heavy grades, particularly the Ogden-Wahsatch district.

The first twenty "Class 1" Big Boys were delivered in 1941 (#4000-#4019), and five more (#4020-#4024), designated "Class 2", in 1944.

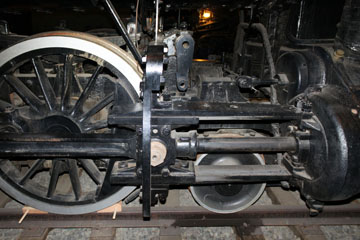

Above, amongst the largest coupled to a steam locomotive and carried on a fourteen wheel

(4 + 10) centipede truck, the tender weighs 342,2000 lbs light and has a capacity of 25,000 gallons of water and 28 tons of coal. With additional steel coal boards fitted at the top of the coal bunker, it could hold as much as 32 tons of coal.

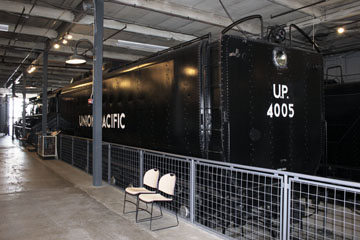

Below left, a view of the conveyor screw that fed coal from the tender to the stoker. Originally, sliding doors were fitted the entire length of the tender floor, except for a small opening at the

front.

Except for the eight survivors, the other

seventeen Big Boys were scrapped between 1961 and 1963.

You can see the other seven surviving Big Boy locomotives on this website: there is a UP #4004 page, #4006 is on the National Museum of Transportation, St. Louis Yard page, #4012 on the

Steamtown page, #4014 on the Southern California RLHS page, #4017 on the National Railroad Museum page, #4018 on the Museum of the American Railroad page and #4023 on the Kenefick Park page.

#4005 was was the only Big Boy converted to

burn oil in 1946 as a test for all the 4000s in response to a threatened disruption of coal supplies because of a coal strike. The test lasted through March 1948 but the firebox design did not allow the oil fire to develop sufficient heat to produce the required steam pressure so #4005 was returned to coal.

By late 1958, #4005 was in storage at Green River, WY. It became part of UP's Heritage Collection housed in Cheyenne, WY, until it was donated to the museum in 1970.

With a 46.27 sq ft grate, 150.8 sq ft firebox and total heating surface of 2,505 sq ft, #444 operated at a boiler pressure of 200 psi delivering 30,940 lbs tractive effort.

#444 was sold in 1958 to the tourist line Black Hills Central Railroad and then to the Forney Transportation Museum in 1968. It is one only two surviving R-1 engines. You can see the other

survivor on the CNW #175 page of this website.

The closeness of the displays makes getting good photos of CNW #444 a little difficult.

Built at Alco's Schenectady, NY, works in 1906, #444 is an oil burning Ten Wheeler (4-6-0) type locomotive weighing 165,000 lbs, 136,000 lbs on its 63" drivers. The engine wheelbase is

25' 10", the driver wheelbase 14' 10", the cylinders are 21" x 26" and the engine has Stephenson link motion valve gear.

This 0-4-4T (Forney Tank) was built at the H. K. Porter Works in Pittsburgh, PA, for Andrew H. Gay, a dealer in Plaquemine, LA, in 1897.

It had many owners including the Cora-Texas Plantation in White Castle, LA, Harold Allen & Casimer Samborski in Ann Arbor, MI, the Marriott Corp., in Dayton, OH, the Illinois Railway Museum and, finally, the Forney Transportation Museum. A 36" gauge coal burner, #1 weighs 36,000 lbs, 25,000 lbs on its 35" drivers. With 10" x 14" cylinders it operated at a boiler pressure of 150 psi, delivering 5,080 lbs tractive effort.

The Forney type locomotive was designed by Matthias Forney. Forney apprenticed with the locomotive builder Ross Winans before joining the Baltimore & Ohio Railroad as a draftsman in 1855. He then worked for the Illinois Central Railroad from about 1861 to 1864 where he patented an 0-4-4T locomotive.

Also built by several other manufacturers, the Forney type was used extensively on elevated railways. However, steam-powered engines on the elevateds lasted only a few years as they were soon replaced by electric engines.

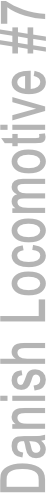

Henschel & Son in Kassel, Germany, built this 24" gauge 0-4-0T (Tank) locomotive in 1930. It worked for an unknown Danish railway line until it was bought in 1961 by Arthur Seifert. In 1962, Seifert sold it to the museum.

A coal burner weighing 24,200 lbs, #7 is equipped with 24" drivers and 9½" x 11¾" cylinders. Operating at a boiler pressure of 170 psi, it delivered 6,250 lbs tractive effort. You can see another Henschel built locomotive on the Northern Queen Inn page of this website and the CBQ #1548 page.

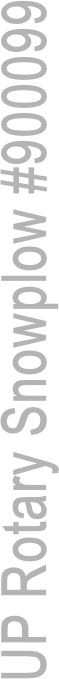

The rotary snowplow was invented by Toronto, ON, dentist J. W. Elliot in 1869. Orange Jull of Orangeville, ON, then developed Elliot's design, building working models he tested with sand. During the winter 1883-1884, Jull contracted with the Leslie Brothers of Toronto to build a full-size prototype that proved successful. Jull later sold his design rights to the Leslie Brothers, who formed the Rotary Steam Shovel Manufacturing Company in Paterson, NJ. The Leslie Brothers contracted with Cooke Locomotive & Machine Works, later part of Alco, in Paterson to carry out the actual construction of their snowplows.

This snowplow was built in 1909 as #099 for the Laramie, Hahns Peak & Pacific Railroad, which operated a one hundred and eleven mile line south from Laramie, WY, to Coalmont, CO. Construction of the line started in 1901, and the first train reached Walden in October 1911 and Coalmont in December.

Traversing quite mountainous terrain, the line was difficult and expensive to operate during winters and, in 1914, the company was unable to pay its mortgage sparking the first of a series of bankruptcies and takeovers.

The rotary mechanism at the front of the plow was operated by a self-

contained steam engine inside the snowplow, but the plow could not move under its own power. It had to be pushed by three or four locomotives from the rear. With this assistance, it was apparently able to

clear snow drifts as high as 15'.

Below, the snowplow was probably built as a coal burner but was later converted to an oil burner.

It was re numbered Colorado, Wyoming & Eastern #099, Northern Colorado & Eastern #099 and Laramie North Park & Western #099 as the line went through its various ownerships.

Built for the Union Pacific Railroad in 1901 as number #02801, this is the oldest known

surviving derrick built by the Industrial Works of Bay City, MI.

Weighing 46,300 lbs with a lift capacity is 40 tons, It was used in the 23rd Street yard in Denver, CO, to move shifted loads on rail cars and to position rail car truck wheels during a change. Originally run on steam from a coal fired boiler, by 1967 it had been converted to run on compressed air as air pressure was available throughout the 23rd St yard to power various tools and equipment.